We produce and provide components, machines, processing and test lines based on technical documentation submitted by our clients.

We manage complex projects basing upon an optimised supply chain of our own integrated with external suppliers as well as upon catalogue parts.

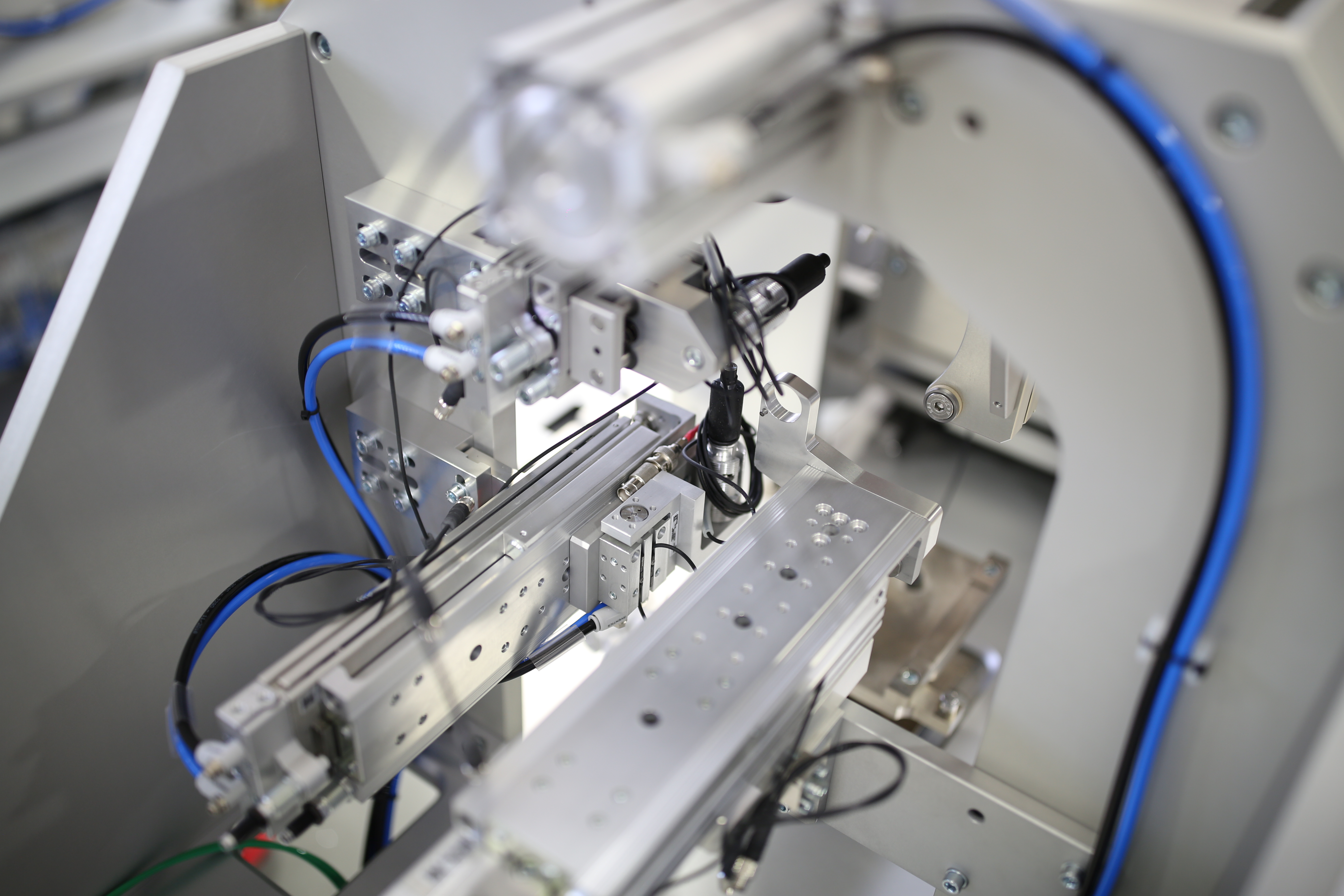

High quality of our products is guaranteed by certified mechanical, electrical, pneumatic and hydraulic competences of our assembling team and professionally equipped workstations.

We have vast experience in assembling components of top manufacturers such as:

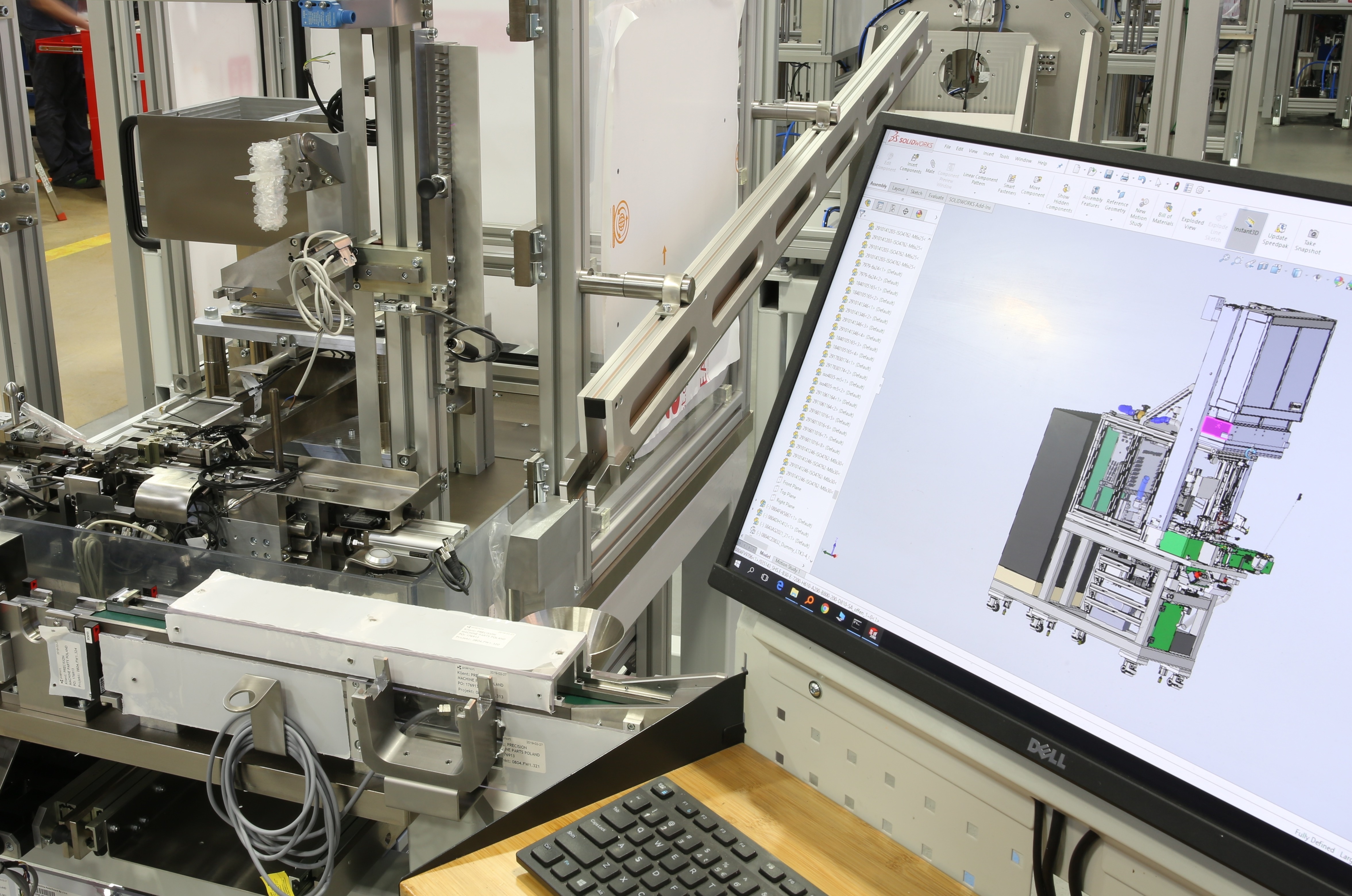

PMP offers flexible build to print solutions for our customers.

We have competent, experienced team and manufacturing technologies which guarantee successful execution of your build to print projects.

Our internal manufacturing departments can quickly react for any changes and modifications which are very typical on every stage on such kind of projects. Based on our internal and external supply chain we can manufacture and deliver your build to print equipment starting from single machines to production lines.

- from prototype to small series

- lean oriented attitude

- fast reaction for modifications and changes

- internal supply chain for machined and sheet metal parts

- state of the art automized manufacturing solutions

- optimized build times

- dedicated project team with transparent way of communication

We are machining experts and use our in-depth knowledge to take full advantage of our high-end machines supported by the latest editions of software such as SolidWorks, SolidCam (including iMachining moduls), Mastercam, PEPS, AutoCAD.

We manufacture details in the field of:

X: 2600 mm

Y: 1100 mm

Z: 1045 mm

Max. turning diameter:

710 mm,

Max. turning length:

2100 mm

Max. diameter: 350 mm

Max. length: 1000 mm

X: 550 mm

Y: 350 mm

Z: 440 mm

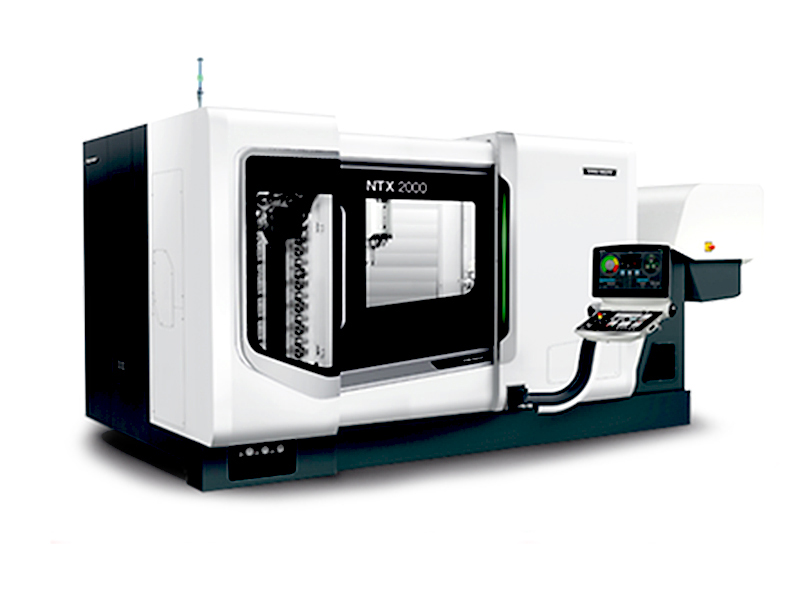

We are equipped with the most recent CNC machining centres supported by automation system

CNC 5 AND 4 AXIS MILLING CENTRES

- Heller FP 4000 + Fastems FPC1500

- Heller FP 4000 + Fastems FPC1500

- DMG Mori DMF 260/11 linear

- DMG Mori DMF 260/7 linear

- DMG Mori DMC 80U duoBlock with Pallet Changer

- Deckel Maho DMU 50 PH150I8 with Pallet Changer

- DMG Mori DMU 50 PH150 with Pallet Changer

- Deckel Maho DMU 100 monoBlock

- Deckel Maho DMU 80 monoBlock

- Deckel Maho DMU 80P duoBlock

VERTICAL CNC MILLING CENTRES

- Haas VF8

- Haas VF8+Automatic Pallet Changer Midaco

- Haas VF-5/40

- Haas VF-5/40+Automatic Pallet Changer Midaco

- Agie Charmilles VCE1200, VCE 1400

- Agie Charmilles VCE800+Work Pal

- Agie Charmilles VCE800W

CNC TURNING CENTRES

- NTX 2000 DMG Mori

- Mori Seiki NL2500

- TUR 630A MN

- TUR 710A X2000

- Weiler E30

- Hyundai WIA L300LMC

INTERNAL AND CYLINDRICAL GRINDING MACHINES

- RUP 350-1000

- Studer Favorit CNC

- Jotes SOJ16

EROSION MACHINES

- GF Agie Charmilles F 440 CCS

- GF Agie Charmilles Cut 300

- GF Agie Charmilles Cut 300 Sp

- Robofil 240 CCS

SURFACE AND PROFILE GRINDING MACHINES

- G+H Schleiftechnik FS 840 ZCC – 2 pcs

- ELB BD10

- ELB smartLine BD10 ZRT XC PRO

We use our hardening shop for internal needs as well as external orders. We offer:

- nitriding

- carbonitriding

- gas carburising

- hardening and tempering of alloy steel

VACUUM FURNACE – SECOWARWICK TYP 25 VPT

– hot zone (WxHxL): 400 mm x 400 mm x 600 mm

– charge: max 200 kg

– working temperature: 1200 °C

ATMOSPHERIC RURNACE – IVA RH -966RVE

– hot zone (WxHxL): 600 mm x 600 mm x 900 mm

– charge: max 600 kg

– working temperature: 750 °C

We are an expert in sheet metal forming; range 0.2 mm – 25 mm

- stainless steel

- carbon steel

- galvanised steel

- aluminium

SHEET METAL LASER MACHINING CENTRES

- Trulaser 3030 fiber

- Trulaser 3030-5000W

BENDING MACHINES

- Trumpf TruBend 5170 – 2 pcs

- Trumpf TruBend 5230

- Trumpf TruBend 7036

- Trumpf ToolShuttle KB24

AUTOMATED STORAGE SYSTEM COMPACT-LAGER 4/234 PALETTE

SHOT BLASTING MACHINE CABILUX PC-CL 533

GRINDING MACHINES

- Fladder Gyro 3000

- MD6 CR 1350 Costa

WELDING MACHINES

- TIG

- MIG-MAG

- LORCH S-RoboMIG XT Cobot Welding System

- MA1-65 THEO laser welding machine with wire feeder